In the world of manufacturing, cutting tools and wear parts are essential for the smooth operation and longevity of industrial equipment. One material that stands out in the production of these parts is tungsten carbide (WC). Renowned for its impressive hardness, wear resistance, and durability, tungsten carbide material has become the go-to choice for applications requiring extreme toughness and resistance to wear.

This article will explore why tungsten carbide is the preferred choice for wear parts, focusing on its properties, advantages, and common applications.

Whether you’re a manufacturer, engineer, or business owner, understanding why tungsten carbide excels in wear parts will help you make more informed decisions when selecting materials for your tools and machinery.

What Is Tungsten Carbide (WC)?

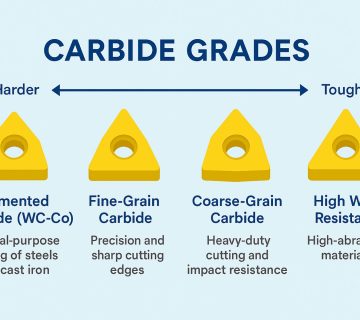

Tungsten carbide (WC) is a compound made from tungsten and carbon. Known for its exceptional hardness and resistance to wear, it is a highly versatile material used in various industries, including mining, drilling, and manufacturing. Tungsten carbide is often alloyed with other materials to improve its strength and toughness, making it ideal for parts subjected to high wear conditions.

Tungsten carbide is often used in applications where strength and durability are paramount, such as cutting tools, wear-resistant parts, and machinery components. The compound’s impressive mechanical properties make it one of the hardest materials available, second only to diamonds.

Why Tungsten Carbide Is Preferred for Wear Parts

When it comes to wear parts, choosing the right material is crucial for ensuring longevity, efficiency, and cost-effectiveness. Tungsten carbide offers several key advantages that make it the preferred material for wear parts.

1. Extreme Hardness and Durability

One of the most significant reasons tungsten carbide is chosen for wear parts is its incredible hardness. Tungsten carbide has a hardness rating of approximately 9 on the Mohs scale, which is just below diamond’s rating of 10. This makes it highly resistant to abrasion, deformation, and wear, even under extreme conditions.

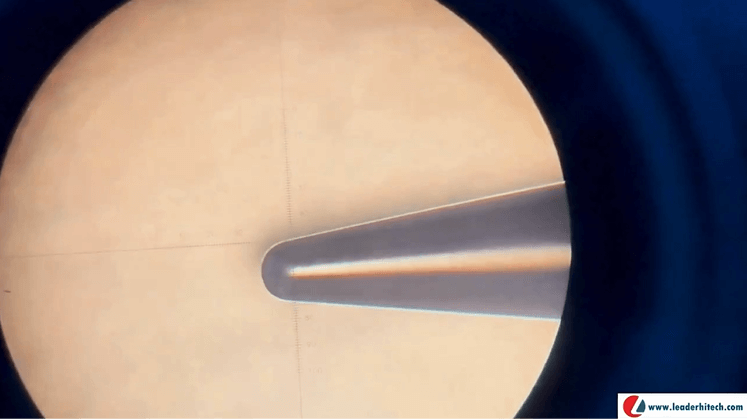

For wear parts that are exposed to continuous friction, such as drill bits, cutting tools, or milling machines, tungsten carbide is an ideal material. Its ability to withstand harsh conditions and maintain its sharpness and shape over time makes it a top choice for industries that require tools that perform under high-stress situations.

2. High Wear Resistance

Tungsten carbide is renowned for its wear resistance, which makes it particularly effective for components that come into frequent contact with other materials. Over time, many materials begin to lose their shape, sharpness, or performance due to friction and abrasion. Tungsten carbide’s resistance to wear means that it can maintain its form and function for much longer than many other materials.

In industries such as mining, where tools are subjected to constant impact and abrasive forces, tungsten carbide wear parts are crucial for reducing downtime and the need for frequent replacements. Components like wear inserts, plates, and tips made from tungsten carbide are designed to last significantly longer, thus improving operational efficiency and reducing maintenance costs.

3. Resistance to Corrosion and Heat

Tungsten carbide also offers impressive resistance to corrosion and high temperatures, making it suitable for applications where wear parts are exposed to moisture, chemicals, and extreme heat. In environments where other materials might degrade or lose strength, tungsten carbide retains its structural integrity.

For example, tungsten carbide parts used in the oil and gas industry, or those exposed to high-temperature environments, offer long-lasting performance because of their ability to withstand corrosion from chemicals and the high heat generated during operation.

4. Improved Efficiency and Cost-Effectiveness

The durability and long life of tungsten carbide wear parts make them more cost-effective in the long run. While tungsten carbide may have a higher initial cost compared to other materials, its extended lifespan and reduced need for replacement parts mean that businesses can save on maintenance and downtime costs. This makes tungsten carbide a sound investment for industries where wear parts are regularly replaced due to high wear rates.

In addition, the increased efficiency and reduced downtime associated with tungsten carbide parts contribute to overall operational cost savings. Machinery and equipment using tungsten carbide wear parts can run longer without interruption, boosting productivity.

5. Versatility and Customization

Another advantage of tungsten carbide material is its versatility. It can be used in a wide variety of applications, from cutting tools to mining equipment and automotive parts. Tungsten carbide can be manufactured in a variety of shapes, sizes, and configurations to meet the specific needs of different industries.

Many manufacturers can customize tungsten carbide parts to suit particular applications, such as creating wear inserts for specific machinery or crafting cutting edges for precision tools. This level of customization ensures that businesses can get the exact material they need to perform in the most demanding environments.

Common Applications of Tungsten Carbide Wear Parts

The extraordinary properties of tungsten carbide make it suitable for a wide range of industrial applications. Some of the most common uses for tungsten carbide wear parts include:

1. Cutting Tools

Tungsten carbide is widely used in the production of cutting tools, such as drill bits, milling cutters, and saw blades. The material’s hardness and wear resistance ensure that these tools maintain their cutting efficiency even after extended use in tough materials.

2. Mining Equipment

In the mining industry, tungsten carbide is used in tools such as drill bits, rock crushers, and excavation equipment. These tools often encounter extremely abrasive conditions, and tungsten carbide’s durability helps extend the life of mining equipment, reducing downtime and maintenance costs.

3. Wear Inserts and Wear Parts

Tungsten carbide wear inserts are commonly used in machinery components that experience continuous wear, such as valves, pumps, and gears. These inserts provide a durable, long-lasting solution that helps prevent premature wear and tear, allowing for smoother operation and improved efficiency.

4. Automotive and Aerospace Parts

Tungsten carbide is also used in the automotive and aerospace industries for components like engine parts, brake pads, and turbine blades. Its ability to withstand high temperatures, pressure, and abrasion makes it ideal for these high-performance applications.

Challenges and Considerations

While tungsten carbide offers many advantages, there are a few considerations to keep in mind. Due to its hardness, tungsten carbide can be more brittle than other materials, meaning it may fracture or crack under certain stress conditions. Therefore, careful design and engineering are required to ensure that the material is used in appropriate applications.

Additionally, tungsten carbide is a dense material, which can make it heavier than alternatives. This may impact certain applications where weight is a concern, such as in some automotive or aerospace parts.

Conclusion

Tungsten carbide has earned its reputation as the preferred choice for wear parts due to its exceptional hardness, wear resistance, corrosion resistance, and versatility. Whether in cutting tools, mining equipment, or automotive parts, tungsten carbide provides a durable and cost-effective solution for industries that demand high-performance materials.

Its ability to withstand extreme conditions and reduce the need for frequent replacements makes it an invaluable asset for businesses seeking to improve their operational efficiency and reduce maintenance costs.

As industries continue to evolve and demand materials that can withstand harsher environments, tungsten carbide will remain at the forefront of wear part technology. Understanding the benefits of this remarkable material and its applications can help businesses make informed decisions and ensure they select the best materials for their needs.

If you’re looking for carbide tips or other tungsten carbide wear parts, check out Leader Hitech for high-quality products tailored to meet your industrial needs.