The semiconductor industry relies on precision at every stage of production. From slicing wafers to assembling delicate microchips, the tools used to separate, shape, and refine materials determine not only efficiency but also quality. Among these, shear tools and cutting tools are often compared.

Although both are designed for material removal or separation, they operate in very different ways. In the context of semiconductors — where accuracy, durability, and minimal contamination are paramount — understanding these differences is essential.

This article explores how shear tools differ from cutting tools, their applications in semiconductor processes, and what materials are best suited for each.

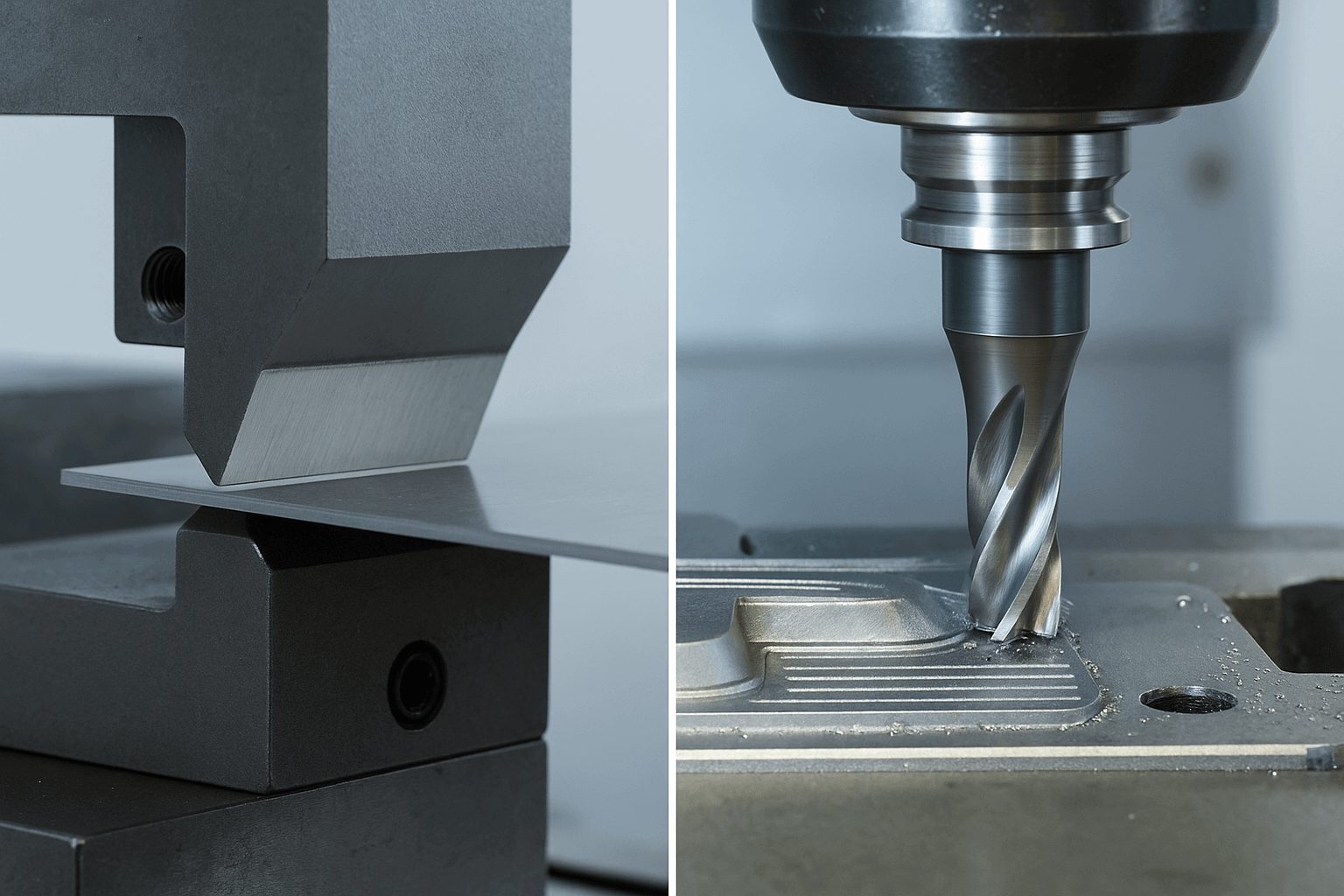

What Are Shear Tools?

Shear tools are specialized instruments that separate material through shearing action. Instead of slicing like a blade, they apply opposing forces in close proximity, causing the material to fail along a line.

Characteristics of Shear Tools in Semiconductors:

- Use compression and opposing force rather than sharp cutting edges.

- Produce clean separations with minimal burrs.

- Commonly used in bond testing and delicate trimming applications.

- Require high-strength, wear-resistant materials to maintain precision over repeated use.

Shear tools are especially valued in semiconductor assembly for their ability to maintain structural integrity while minimizing contamination from excess debris.

What Are Cutting Tools?

Cutting tools are designed to remove or divide material using a sharp edge that penetrates the surface. Unlike shearing, cutting involves chip formation or slicing actions, where material is physically separated by displacement.

Characteristics of Cutting Tools in Semiconductors:

- Use sharp edges to slice or shape materials directly.

- Ideal for precision machining such as dicing wafers, drilling, or micro-milling.

- Can be applied to metals, ceramics, and silicon with specialized coatings.

- Often rely on advanced manufacturing like diamond-tipped blades or laser cutting.

In semiconductor production, cutting tools provide the high accuracy needed for processes like wafer dicing, but they must be carefully selected to avoid microcracks or contamination.

Key Differences Between Shear Tools and Cutting Tools

| Aspect | Shear Tools | Cutting Tools |

| Working Principle | Applies opposing forces to fracture material | Uses a sharp edge to slice or remove material |

| Material Removal | Minimal displacement, clean breaks | Produces chips, shavings, or kerfs |

| Applications | Bond testing, lead frame trimming, component shearing | Wafer dicing, drilling, micro-milling |

| Surface Finish | Smooth edges, minimal burrs | May require post-processing for fine finish |

| Speed and Efficiency | High-speed, effective for repetitive separations | Precision-driven, may be slower in fine work |

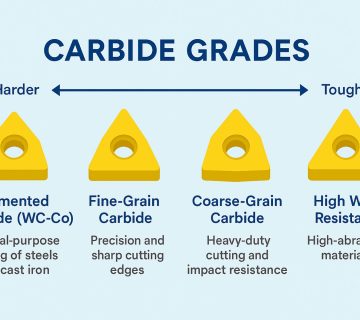

| Tool Material Needs | Requires very hard, durable shear pin material | Requires sharpness retention, often diamond- or carbide-coated |

Applications in the Semiconductor Industry

Shear Tools in Semiconductors

- Bond Testing – Shear tools are used to test the strength of wire bonds and solder joints, ensuring reliability of semiconductor packaging.

- Lead Frame Trimming – In packaging, shear tools cleanly separate excess metal without introducing contamination.

- Component Shaping – Used in processes where precise force application is critical without compromising component integrity.

Cutting Tools in Semiconductors

- Wafer Dicing – Cutting tools such as diamond blades or lasers are used to separate silicon wafers into individual chips.

- Micro-Machining – Cutting tools enable drilling, slotting, or shaping semiconductor materials with extreme accuracy.

- Packaging and Assembly – Applied in trimming and forming delicate parts during component assembly.

Best Materials for Shear Tools in Semiconductors

To ensure precision and longevity, shear tools must be made from hard, wear-resistant materials. Some of the best options include:

- Tungsten Carbide – Offers high hardness and resistance to wear, commonly used for shear pins.

- Ceramic Alloys – Provide excellent stability at high temperatures, suitable for clean, burr-free shearing.

- High-Speed Steel (HSS) – Durable and relatively cost-effective, though less wear-resistant than carbide.

- Diamond-Coated Alloys – Increasingly used for extreme durability and precision in high-volume applications.

The choice depends on the required tolerance, load, and application environment.

Advantages of Shear Tools and Cutting Tools

Shear Tools

- Provide clean, burr-free separations, making them suitable for sensitive processes.

- Offer high repeatability and durability, ensuring consistent performance in high-volume applications.

- Designed for minimal contamination, an important factor in semiconductor manufacturing.

Cutting Tools

- Highly versatile, with applications across different semiconductor materials.

- Deliver high precision, making them ideal for detailed machining and wafer processing.

- Compatible with a variety of methods, including mechanical, diamond, and laser-assisted cutting.

Practical Considerations in Tool Selection

When deciding between shear and cutting tools in semiconductor processes, engineers should consider:

- Nature of the Task – Is the requirement bulk material separation (shearing) or precision shaping (cutting)?

- Material Properties – Brittle materials like silicon may require specialized cutting, while metals may benefit from shearing.

- Contamination Risk – Processes sensitive to debris may prefer shear tools.

- Production Scale – High-volume manufacturing often relies on the efficiency of shear tools, while specialized cutting tasks may require slower, more precise cutting tools.

Conclusion

Both shear tools and cutting tools play vital roles in the semiconductor industry, but they are far from interchangeable. Shear tools excel in tasks requiring clean separations and bond testing, while cutting tools dominate precision machining and wafer processing.

For engineers, the key lies in selecting the right tool for the task — considering efficiency, precision, contamination risk, and material type. Ultimately, combining the strengths of both ensures the highest standards in semiconductor production.

👉 Shear or cut — the right tool makes all the difference in semiconductor quality and reliability.

✅ Precision Tools for Semiconductor Excellence

At Leader Hitech, we deliver high-performance shear tools and precision components engineered for the semiconductor industry. Our expertise ensures durability, accuracy, and reliability across every application.

👉 Explore our solutions today and power your production with trusted innovation.