In precision engineering and manufacturing, shear tools play a critical role in shaping, cutting, or testing materials. From large-scale metal fabrication to delicate microelectronics, these tools apply controlled force to cut, separate, or test components.

However, not all shear tools are built the same. The requirements for an industrial workshop differ vastly from those of a semiconductor cleanroom. While both serve the same mechanical principle — applying shear force — their design, material composition, and precision levels set them apart.

This article explores the key differences between semiconductor shear tools and industrial shear tools, what factors affect their lifespan, and how to choose the right one for your application.

What Are Shear Tools?

At their core, shear tools are cutting or machining tools designed to apply precise force to separate materials without melting, tearing, or deforming them. They’re commonly used in:

- Manufacturing and metalworking: cutting metal sheets, trimming excess material, or shaping parts.

- Semiconductor and electronics industries: testing the strength of micro-bonds, leads, and dies during quality control.

While industrial shear tools are built for high loads and durability, semiconductor shear tools demand microscopic precision, cleanliness, and consistency — even the slightest deviation can affect product integrity.

What Are Shear Tools in Semiconductor Applications?

In the semiconductor industry, shear tools are used primarily in bond testing, die shear testing, and micro-component strength analysis. They measure how much force a microchip, wire bond, or solder joint can withstand before failing — ensuring long-term reliability of integrated circuits and sensors.

Key Characteristics of Semiconductor Shear Tools

1. Micron-Level Precision

Semiconductor components are often smaller than a strand of hair. As such, shear tools in this field must operate within micron tolerances to deliver accurate and repeatable test results.

2. Cleanroom Compatibility

These tools must meet stringent cleanliness and contamination control standards. Even microscopic debris or residue from a tool can compromise test accuracy or damage sensitive chips.

3. High Repeatability and Stability

Semiconductor shear tools are engineered for consistent test performance — the same shear force and positioning must be replicated hundreds of times without variation.

4. Premium Materials

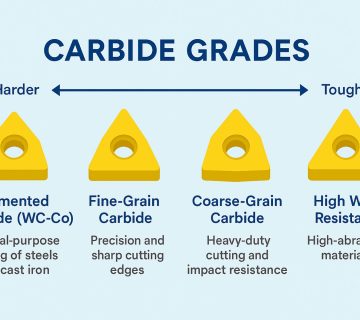

Common materials include:

- Tungsten carbide: for high wear resistance and hardness.

- Stainless steel: for structural stability and corrosion resistance.

- Diamond-coated tips: for ultra-high precision and extended life span.

5. Specialised Coatings

- TiN (Titanium Nitride): enhances hardness and reduces friction.

- DLC (Diamond-Like Carbon): prevents wear and contamination.

- Nano-coatings: improve chemical resistance and surface smoothness for delicate testing.

These characteristics ensure that semiconductor shear tools can perform at a micro level — delivering accuracy, cleanliness, and reliability essential for advanced electronics manufacturing.

What Are Shear Tools in Industrial Applications?

In contrast, industrial shear tools are designed for heavy-duty cutting, shaping, or machining in fields like metalworking, automotive production, and construction. Their focus is not microscopic accuracy but strength, durability, and throughput.

Common Uses of Industrial Shear Tools

- Cutting large metal sheets and plates.

- Trimming excess materials in fabrication.

- Punching and forming metal components.

- Preparing workpieces for welding or assembly.

Key Features of Industrial Shear Tools

- High Load Capacity

Industrial shear tools withstand large-scale forces to cut through thick materials efficiently. - Larger Tolerances

Precision in industrial shearing is measured in millimeters, not microns. This is sufficient for general fabrication where micro-accuracy isn’t required. - Durability Over Precision

These tools prioritise longevity and cost-effectiveness over pinpoint accuracy. - Material Composition

Typically made of hardened steel, tool steel, or alloy composites capable of handling repetitive stress and vibration. - Operating Environment

Used in workshops, production lines, or outdoor settings — far less controlled than semiconductor cleanrooms.

Key Differences Between Semiconductor and Industrial Shear Tools

While both types share the same mechanical concept, their applications and engineering priorities differ greatly.

| Aspect | Semiconductor Shear Tools | Industrial Shear Tools |

| Precision | Operate within micron-level tolerances for bond testing | Operate within millimeter tolerances for cutting and shaping |

| Material | Tungsten carbide, diamond-coated, stainless steel | Tool steel, carbon steel, alloy steel |

| Coating | TiN, DLC, nano-coatings | Anti-rust or hardening coatings |

| Environment | Cleanroom or laboratory | Factory or workshop |

| Purpose | Quality control and reliability testing | Cutting, trimming, forming materials |

| Force Scale | Low-force, high-precision | High-force, heavy-duty |

| Cost | Higher due to precision and materials | Lower, focused on mass production |

| Maintenance | Requires cleaning and calibration | Requires sharpening and lubrication |

In essence, semiconductor shear tools are precision instruments, whereas industrial shear tools are production workhorses.

What Factors Affect the Lifespan of a Semiconductor Shear Tool?

The longevity of a semiconductor shear tool depends on multiple factors, from material quality to maintenance practices. Below are the most influential ones:

- Material and Coating Selection

Harder materials like tungsten carbide and coatings like DLC or TiN significantly extend lifespan by reducing friction, corrosion, and wear. - Operating Force and Load Consistency

Applying excessive or uneven force during bond testing can lead to tip deformation or micro-fractures. Using the correct calibration ensures uniform stress distribution and longer tool life. - Cleanliness and Contamination Control

Semiconductor testing demands a clean environment. Dust, oil, or residue can cause abrasion or interference, shortening tool performance life. - Maintenance and Handling

Regular cleaning, inspection, and careful handling prevent surface damage and contamination. Even a minor scratch on a tip can lead to inaccurate test readings. - Application Frequency

Frequent, high-cycle operations accelerate wear. Monitoring usage data helps schedule timely replacements or reconditioning. - Tool Geometry and Alignment

Improper alignment or incorrect geometry can create uneven stress, reducing both accuracy and service life. Precision calibration is crucial before each use.

By managing these factors, manufacturers can maximize the lifespan and consistency of their semiconductor shear tools, minimizing downtime and replacement costs.

How to Choose the Right Shear Tool for Your Application

Selecting the right shear tool requires a clear understanding of your application type, precision requirements, and operating environment.

Here’s what to consider:

- Define Your Objective

- For bond testing or microelectronics, choose semiconductor-grade shear tools with cleanroom compatibility and nano-coatings.

- For metal fabrication or automotive manufacturing, use industrial shear tools designed for durability and cutting power.

- Match Material and Coating to Your Needs

- Use diamond-coated or tungsten carbide tips for micro-precision.

- Choose hardened or alloy steels for heavy-duty cutting applications.

- Evaluate Supplier Expertise

Not all manufacturers specialize in both segments. For semiconductor use, ensure your supplier understands micron-level geometry, surface finishing, and contamination control. - Prioritise Longevity and Support

Look for suppliers that offer regrinding, tip replacement, and calibration services to maintain tool consistency over time. - Budget Wisely

While semiconductor shear tools have a higher upfront cost, they offer greater repeatability, precision, and long-term value.

Conclusion: Precision Defines the Difference

Both semiconductor shear tools and industrial shear tools share a common purpose — to apply shear force effectively. Yet, their engineering intent, material selection, and accuracy levels distinguish them completely.

For semiconductor applications, precision, cleanliness, and repeatability take priority. For industrial applications, durability, power, and efficiency lead the way.

Understanding these distinctions helps engineers and manufacturers select the right shear tool for their task — optimizing performance, reducing downtime, and extending tool lifespan.

Ready to achieve cutting-edge precision in semiconductor testing?

👉 Explore LeaderRange Hitech’s precision shear tools, engineered for semiconductor and microelectronics applications. Designed for accuracy, reliability, and long-term durability.