Have you ever wondered what makes one tiny shear pin outperform another in the high-stakes world of semiconductor testing? 🧪

In semiconductor manufacturing, where even the slightest variation can affect performance, the smallest tools often play the biggest roles. Take the shear pin, for example—it’s used to apply precise force and measure the strength of microelectronic bonds like wire or die attachments.

But here’s something many people don’t realise: not all shear pins are the same. One key factor that can dramatically impact their performance is the surface coating. Especially in high-throughput environments, the right coating can make the difference between consistent results and costly inconsistencies.

In this article, let’s break down two popular options—DLC (Diamond-Like Carbon) and TiN (Titanium Nitride)—and help you decide which is the better fit for your semiconductor application.

Why Surface Coating Matters for Shear Pins

Let’s begin with the basics. A shear pin is designed to apply precise force on semiconductor bonds, such as wire bonds or ball grid arrays (BGAs). During repeated testing, these pins are exposed to:

- High mechanical stress

- Constant abrasion

- Potential contamination

- Extremely tight tolerances (often ±1 μm)

Without a robust coating, shear pins can wear out quickly, lose dimensional integrity, and even contaminate the test area. This is where coatings like DLC and TiN step in to prolong lifespan and maintain accuracy.

Meet the Contenders: DLC vs. TiN

Both DLC and TiN are thin-film coatings applied through processes like Physical Vapour Deposition (PVD) or Chemical Vapour Deposition (CVD). Here’s a quick overview of each:

| Property | DLC (Diamond-Like Carbon) | TiN (Titanium Nitride) |

|---|---|---|

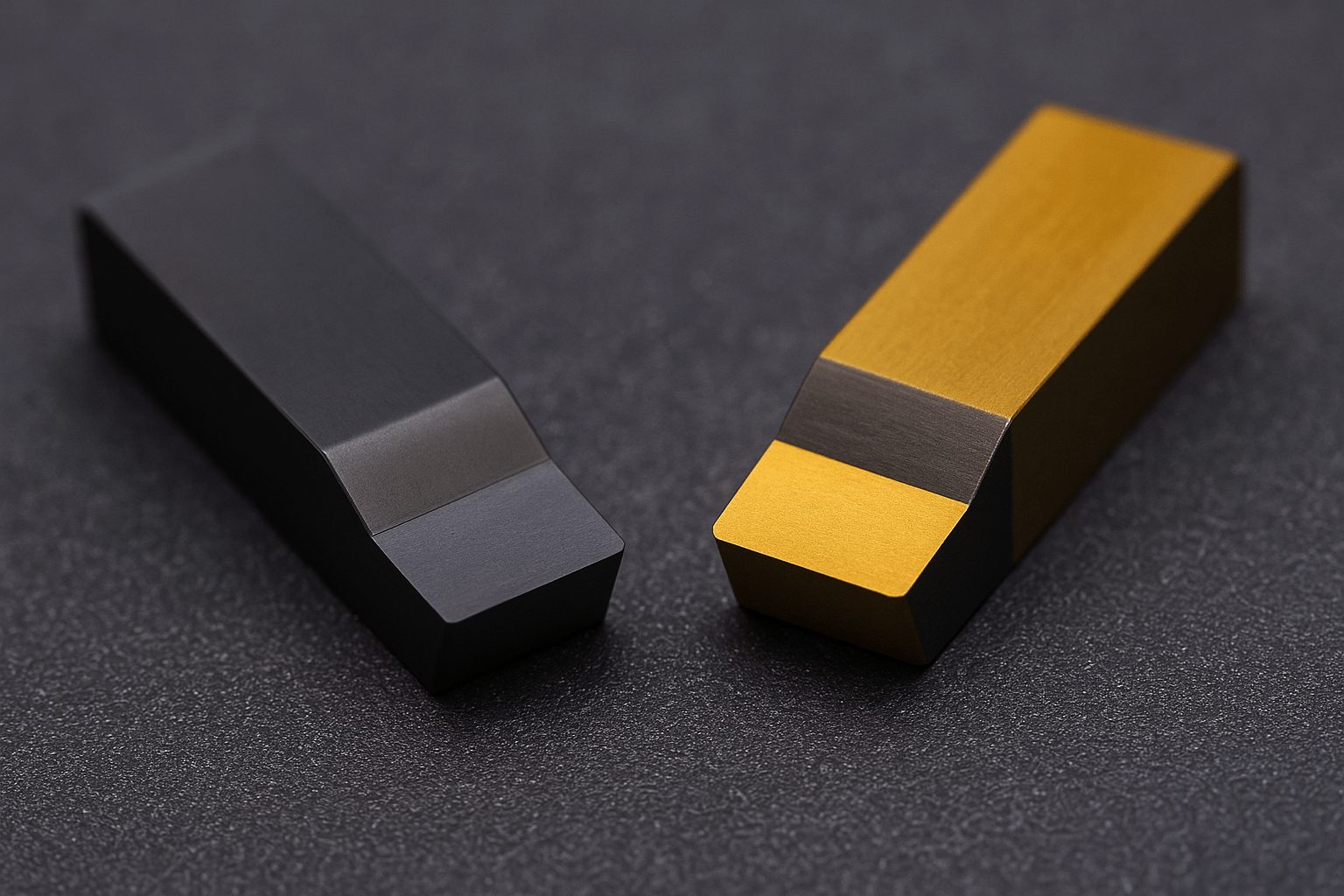

| Appearance | Dark grey to black | Gold-coloured |

| Hardness | ~2000–5000 HV | ~1800–2100 HV |

| Friction coefficient | Extremely low (~0.05–0.1) | Moderate (~0.4–0.6) |

| Thickness range | ~1–3 μm | ~1–5 μm |

| Cleanroom compatibility | Excellent (low particle generation) | Good |

| Cost | Higher | Moderate |

Why Each Property Matters for Shear Pins in Semiconductor Applications

1. Appearance

Although appearance might seem like a minor detail, it actually plays a useful role in daily operations. The colour difference between DLC (dark grey to black) and TiN (gold) allows quick visual identification.

This makes it easier for engineers and technicians to distinguish between tools during setup, inspections, or replacements—especially when multiple coatings are used within the same cleanroom environment.

2. Hardness

Hardness is a critical property when it comes to shear pins because it directly affects how well the pin maintains its edge and shape over time. DLC coatings, with their significantly higher hardness, offer excellent resistance to wear and deformation. This means they stay sharper for longer and perform more consistently in high-cycle or automated testing environments.

While TiN also provides solid durability, it may not hold up as long under continuous, high-pressure use.

3. Friction Coefficient

The smoother the contact surface of the shear pin, the less likely it is to collect residue from materials like gold wire, copper pads, or solder balls. DLC coatings offer an ultra-low friction coefficient, which means there’s minimal drag when the pin makes contact with the bond surface.

This not only reduces the chance of debris sticking to the pin but also helps improve consistency in shear test results. In contrast, TiN has a moderately higher friction level and may require more frequent cleaning to maintain optimal performance.

4. Coating Thickness

The thickness of the coating impacts how precisely the tool can be manufactured and how well it retains sharp edges. DLC coatings are typically thinner and more uniform, making them ideal for ultra-fine pin tips where micrometre-level tolerances are necessary.

TiN coatings, while slightly thicker, still fall within acceptable ranges for most applications and offer solid protection—particularly for shear pins with slightly larger geometries or those used in less demanding environments.

5. Cleanroom Compatibility

In semiconductor manufacturing, cleanliness isn’t optional—it’s a requirement. Many QA and production lines operate in Class 100 or even stricter cleanrooms, where particle control is crucial.

DLC’s inert, ultra-smooth surface generates fewer particles during mechanical stress, making it an excellent choice for contamination-sensitive applications. TiN also performs well in cleanrooms, but its slightly higher wear rate may increase the potential for microparticle generation over time.

6. Cost

Cost is often a deciding factor, especially when balancing performance needs with budget constraints. DLC coatings are more expensive to apply due to the advanced deposition techniques involved, but they tend to last longer and require less maintenance.

For companies running high-volume, precision-critical tests, DLC often provides better long-term value. On the other hand, TiN is a more budget-friendly option and perfectly suitable for lower-frequency tests or scenarios where absolute precision is not mission-critical.

What Is DLC Coating?

Diamond-Like Carbon is a carbon-based coating that mimics the properties of natural diamond—high hardness, chemical inertness, and ultra-low friction. It’s become a popular choice in high-precision applications including medical tools, aerospace, and semiconductor tooling.

✅ Advantages of DLC for Shear Pins:

- Exceptional wear resistance – ideal for high-cycle bond testing

- Low friction – reduces material build-up on the pin face

- Chemical stability – resists oxidation and corrosion

- Non-stick properties – limits bonding pad contamination

🚫 Limitations:

- More expensive than TiN

- Requires precise deposition control

- Slightly more brittle than TiN under extreme shock loads

What Is TiN Coating?

Titanium Nitride is a ceramic material widely used for cutting tools, forming dies, and precision components. Its iconic gold colour is instantly recognisable, and for good reason—it offers a reliable balance of hardness and chemical resistance.

✅ Advantages of TiN for Shear Pins:

- Tough and wear-resistant – protects the pin from mechanical fatigue

- Cost-effective – suitable for medium-duty or short-run testing

- Oxidation-resistant – withstands exposure to air and moisture

- Good adhesion – forms a durable bond with metallic substrates

🚫 Limitations:

- Higher friction than DLC – more debris may stick to the tip

- Wears out faster in ultra-high cycle environments

- May generate slightly more particles during use

Head-to-Head Comparison in Semiconductor Testing

Let’s now look at how DLC and TiN coatings perform across five key factors relevant to shear pin usage in the semiconductor industry.

1. Wear Resistance

- DLC wins here. With superior hardness and low friction, it significantly reduces tool wear even in aggressive, automated environments.

2. Contamination Control

- DLC’s smooth surface and chemical inertness make it cleanroom-friendly, with fewer particles generated during use. Critical for Class 100 or cleaner conditions.

3. Testing Consistency

- DLC-coated pins maintain tip geometry longer, ensuring consistent shear force results over thousands of tests.

4. Cost Efficiency

- TiN is more budget-friendly, especially for companies with short testing cycles or lower test volumes. DLC offers better ROI over time, but higher upfront cost.

5. Regrinding and Recoating

- TiN is easier to regrind and recoat. DLC requires careful handling during recoating, as improper methods can compromise coating integrity.

Which Should You Choose?

Here’s a practical breakdown based on your priorities:

| Use Case | Recommended Coating |

|---|---|

| High-volume, automated shear testing | DLC |

| Cleanroom Class 100 and above | DLC |

| Manual testing or lower frequency use | TiN |

| Cost-sensitive projects with moderate wear | TiN |

| When non-stick tip performance is critical | DLC |

Final Thoughts

Choosing between DLC and TiN coatings for your shear pins isn’t just a matter of budget—it’s about performance, consistency, and the long-term quality of your semiconductor testing process. DLC offers superior wear resistance and cleanliness, while TiN remains a versatile, cost-efficient option for lighter workloads.

By understanding your specific use case, you can select the coating that ensures longer tool life, more accurate test results, and fewer disruptions in your production or QA workflow.