High-Quality Die Bond Tools for Precision Applications

Explore our range of premium die bond tools, designed for accuracy and reliability in microelectronic assembly. Our offerings include ejector needles for precise die placement, rubber tips for delicate handling, and carbide tips for durability and long-lasting performance. Additionally, we provide epoxy stamping tools, ideal for controlled adhesive applications. Whether you require tools for high-precision tasks or robust solutions for demanding environments, our die bond tools deliver exceptional results tailored to your needs.

Upgrade your assembly process with our expertly crafted tools, built to ensure efficiency and precision in every application.

Pepperpots and needle holders are typically used for setting the pattern of ejection.

This depends much on the suitability of the dies and parameter setting which is usually decided by the engineer.

Dispensing tools are commonly used for large dies epoxy pattern. This can range from 1x1mm to 50x50mm dies. We supply all types of nozzle patterns to accommodate todays complex die designs. We’ve fabricated some very complex design for special applications. Generally the design and selection of nozzle will depend much on epoxy viscosity and dispensing pattern.

Dispensing tools are commonly used for large dies epoxy pattern. This can range from 1x1mm to 50x50mm dies. We supply all types of nozzle patterns to accommodate todays complex die designs. We’ve fabricated some very complex design for special applications. Generally the design and selection of nozzle will depend much on epoxy viscosity and dispensing pattern.

The Vespel collet is a popular choice for high temperature application. We supply two variation of vespel (SP-1 & SP-21). Standard vespel max working temperature is 288°C – 482°C (Intermittent). This is suitable for applications which are subjected to high heat and has a sensitive pick up surface. The Vespel plastic characteristic compliments Dies & LED packages.

Carbide pick up tool is excellent for sorting processes. The 85-82HRC material has an impressive wear rate for long lifespan. The max working temperature for this tool is up to 2000 °C and can be mirror surface finished. This gives the tool a glossy and extremely flat surface for maximum contact area.

Our rubber tips are made to cater from bump dies to LED packages. Our standard rubber tips uses NBR (Nitrile Butadine Rubber) & our high temperature variation uses Viton.

The max working temperature can reach up to 250°C. Rubber collets are great for sensitive surface dies which requires a lot of cushioning during pick up.

We also have a variation of material hardness from 50HRC to 80HRC for your selection.

We do plenty of customization for complex application

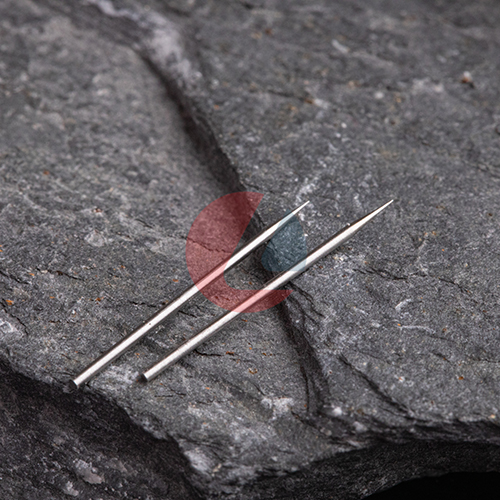

Ejector pins are commonly used for the pick up process ejection. We supply a variety of material to accommodate the sensitivity of the application. We have Tungsten Carbide/ High Speed Steel/ Red Ultem Plastic/ Translucent Ultem Plastic in the order of hardest to softest material. Generally the selection will depend much on the dies dimensions, material, and default setting of the needle holder.

Frequently Asked Questions

What is die bonding in semiconductor manufacturing?

Die bonding, also referred to as die attach, is a key process in semiconductor manufacturing. It involves securely attaching a semiconductor die to a substrate, package, or lead frame. This step is critical as it provides a stable foundation for subsequent processes, such as wire bonding and encapsulation, ensuring the die remains properly positioned for reliable performance in the final electronic device.

What are the advantages of using die bonding in semiconductor manufacturing?

The advantages of using die bonding in semiconductor manufacturing include:

- High Precision in Die Placement: Ensures accurate alignment of the die, critical for optimal performance and seamless integration with other components.

- Strong Mechanical and Thermal Connections: Provides robust structural integrity and effective heat dissipation, enhancing the durability and efficiency of the device.

- Versatility: Accommodates various die sizes and types, making it suitable for a wide range of semiconductor applications.

These benefits are vital for ensuring the performance, reliability, and longevity of semiconductor devices.