Category: Die Bond Tools

The Epoxy Stamping Tool, also known as a transfer or printing tool, is designed for precise epoxy application on large dies, ranging from 1×1 mm to 50×50 mm in size. These tools are essential for dispensing epoxy in complex patterns required by modern die designs. We offer a variety of nozzle patterns tailored to different dispensing needs, ensuring compatibility with a wide range of epoxy viscosities and application requirements.

Our Epoxy Stamping Tools are customizable, allowing for the creation of complex designs for special applications. The choice of nozzle design and configuration is based on factors like epoxy viscosity and dispensing pattern, ensuring optimal performance and accuracy.

Our Variety of Epoxy Stamping Tools

Round ASM Stamping Tools

Micro Series Shank 1.50mm (Tip size: <4mil)

Series Shank 1.50mm (Tip size: >4mil)

Multi-Pin ASM Stamping Pins

Shank 1.50mm

Shank 2.20mm

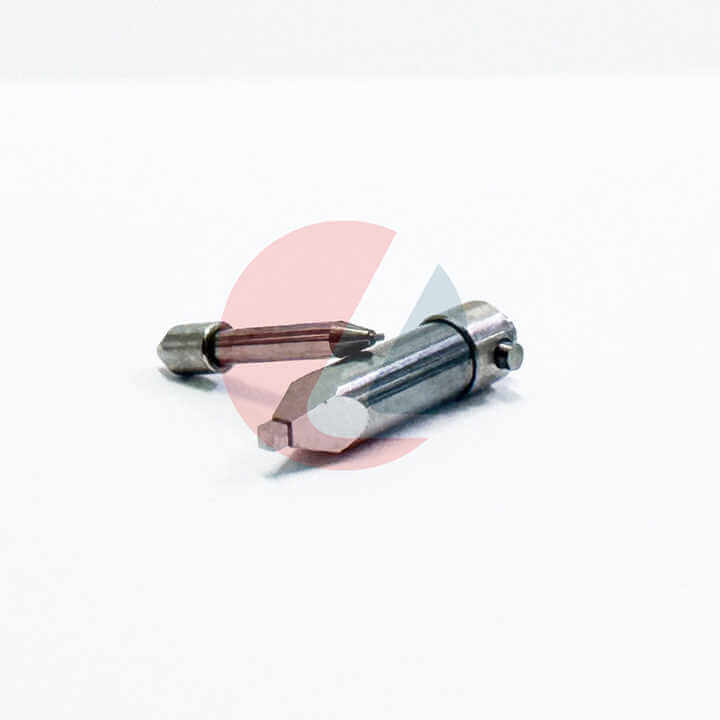

Single-Pin ASM Stamping Pin

Shank 2.20mm

Examples of epoxy stamping tools available include Twin Fork Tips, Fork Tips, Flat Tips, and Round Tips, each designed for specific applications in semiconductor manufacturing.

Customized Stamping Pins

Hard, High Heat Resistance and Durable Material: Carbide (HRC 85)

Applicable Industries: Semicon Die Bond Flip Chip Machine

Frequently Asked Questions About Epoxy Stamping

What Is an Epoxy Stamping Tool?

An epoxy stamping tool, also commonly known as a transfer or printing tool, is a specialized device used in the semiconductor manufacturing process, particularly for creating precise patterns or shapes on semiconductor wafers. It is made from epoxy resin, a durable and chemically resistant material that enables the tool to withstand high-pressure stamping and repetitive use.

How Does an Epoxy Stamping Tool Improve Die Bonding Accuracy?

An epoxy stamping tool improves die bonding accuracy by precisely dispensing epoxy in controlled patterns, ensuring even coverage and uniform thickness on the die surface.

This precision minimizes the risk of air pockets, uneven bonds, and material waste, leading to stronger, more reliable bonds. The tool’s customizable nozzles also allow for tailored dispensing, ensuring optimal application based on die size and design, further enhancing the overall bonding accuracy.

Can Epoxy Stamping Tools Be Customized for Complex Die Designs?

Yes, epoxy stamping tools can be fully customized to accommodate complex die designs. We offer a range of nozzle patterns tailored to specific applications, including intricate dispensing for irregular shapes or detailed patterns.

By adjusting the nozzle design, we can ensure that the epoxy is applied accurately, even for specialized or highly complex die geometries, making them versatile for various semiconductor manufacturing needs.

About LeaderRange Hitech Sdn Bhd

At LeaderRange HiTech, we specialize in providing high-performance epoxy stamping tools designed to meet the precise needs of the semiconductor industry. With a focus on quality and innovation, our tools ensure accurate and consistent epoxy dispensing for a wide range of die sizes and complex designs.

In addition to epoxy stamping tools, we also offer a range of precision accessories such as ejector pins, carbide tips, shear pins, and rubber tips, which are essential components in various stages of semiconductor assembly and testing.

Whether for standard or specialized applications, our epoxy stamping tools deliver reliable results, enhancing bonding accuracy and minimizing material waste. Committed to customer satisfaction, we offer customizable solutions tailored to your specific requirements, serving both local and international markets with excellence.