In the precision-driven world of semiconductor manufacturing, every component plays a vital role in determining product quality and consistency. Among these components, ejector pins may appear small, but their impact is significant. They ensure molded semiconductor parts are released smoothly from molds without damage, deformation, or contamination.

Choosing the right ejector pins manufacturer is not simply a purchasing decision — it’s a strategic move that affects yield rates, product performance, and long-term manufacturing efficiency.

This article explores what to look for when selecting an ejector pin manufacturer for semiconductor applications, including location, product variety, and application suitability.

Understanding the Role of Ejector Pins in Semiconductor Applications

Ejector pins are precision components used in injection molds and die-casting molds to eject finished parts after the molding process. In semiconductor applications, they are often used in encapsulation, micro-molding, and test tooling — areas that demand extreme accuracy, surface finish, and material purity.

A typical ejector pin must:

- Withstand high temperatures and repeated stress cycles.

- Maintain precise dimensional tolerances (often within microns).

- Prevent contamination or particle shedding that could damage wafers or encapsulated devices.

- Deliver consistent performance even in cleanroom or vacuum conditions.

Because semiconductor components are smaller and more fragile than standard molded parts, standard industrial ejector pins are often not suitable. Choosing the right manufacturer ensures you receive pins that are engineered for micro-scale precision, reliability, and longevity.

Why Selecting the Right Ejector Pins Manufacturer Matters

In semiconductor production, tool wear or variation as small as 5 microns can cause defects, alignment errors, or component rejection. A reputable ejector pins manufacturer ensures:

- Precision and consistency — Every pin matches exact specifications, batch after batch.

- Material quality — High-performance alloys resist fatigue, wear, and corrosion.

- Cleanroom compatibility — Pins are polished and finished to prevent particulate contamination.

- Customisation — Manufacturers understand that semiconductor molds often need non-standard geometries.

- Technical support — Collaboration with the manufacturer helps in selecting the right coating, hardness, and pin type for your specific application.

Key Factors to Consider When Choosing an Ejector Pins Manufacturer

Selecting an ejector pin supplier is about more than comparing price lists. The right manufacturer becomes a long-term partner in achieving precision, efficiency, and yield optimization.

Below are the essential factors to consider when making your choice.

1. Consider the Manufacturer’s Location

Location matters more than most buyers realise, especially in semiconductor manufacturing, where lead time, support, and logistics can impact project schedules.

a) Proximity and Lead Time

Manufacturers located within your region or country can provide faster turnaround times for custom orders, replacements, or urgent shipments. Semiconductor production lines operate on tight schedules — downtime due to late parts delivery can cost thousands in losses.

b) Local Technical Support

A nearby ejector pins manufacturer can provide on-site consultations or immediate technical assistance, ensuring problems are resolved quickly. This level of service is particularly valuable during prototype stages or when fine-tuning mold designs.

c) Global vs. Local Manufacturing

- Global manufacturers often offer extensive catalogues, advanced materials, and R&D capabilities.

- Local manufacturers excel in quick communication, lower shipping costs, and flexible customization.

The ideal choice depends on your operational scale. Large fabs may prefer globally established brands with proven quality certifications, while smaller facilities benefit from the agility of local specialists.

2. Check Product Variety and Manufacturing Capability

The best ejector pins manufacturers don’t just produce one standard model — they offer a wide variety designed to suit different molds, temperatures, and materials.

a) Common Types of Ejector Pins

- Straight Ejector Pins: The most common type, used for general mold release.

- Shoulder Ejector Pins: Offer a strong seating surface for high-force ejection.

- Flat Ejector Pins: Used in molds with narrow or thin cavities.

- Step Ejector Pins: Designed for specialized molds requiring specific depth tolerances.

For semiconductor applications, precision variants such as micro-diameter or carbide-coated pins are preferred for longevity and dimensional control.

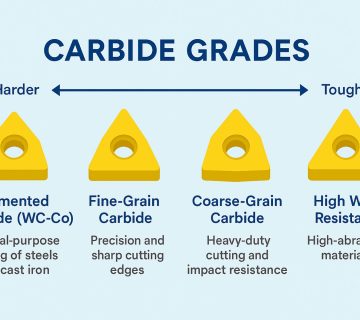

b) Materials and Hardness Options

High-quality ejector pins are typically made from:

- H13 tool steel: Provides toughness and heat resistance.

- SKD61 (equivalent to H13): Offers excellent machinability and polishability.

- Tungsten carbide: Ideal for extreme wear and temperature resistance.

- Stainless steel (SUS420J2): Used for cleanroom and anti-corrosion applications.

For semiconductor molds, tungsten carbide and high-polished stainless steel are often recommended due to their low particle generation and long wear life.

c) Coatings and Surface Treatments

Surface finish is critical in semiconductor environments. The right coating reduces friction, contamination, and wear.

Common coatings include:

- TiN (Titanium Nitride): Improves surface hardness and lubricity.

- DLC (Diamond-Like Carbon): Minimises friction and prevents sticking.

- CrN (Chromium Nitride): Offers excellent corrosion resistance.

Manufacturers with in-house coating technology ensure tighter process control, consistent quality, and shorter lead times compared to outsourced coating facilities.

3. Factor in Your Application Requirements

Not all ejector pins are suitable for semiconductor-level precision. When assessing a manufacturer, consider how well their products align with your specific application environment.

a) Cleanroom Compatibility

Semiconductor components are produced in ultra-clean environments. Choose manufacturers that:

- Adhere to ISO Class 5–7 cleanliness standards.

- Offer pins that undergo ultrasonic cleaning and vacuum packaging.

- Provide non-contaminating coatings or materials that resist oxidation and particle shedding.

b) Temperature and Pressure Tolerance

Molding temperatures in semiconductor encapsulation processes can exceed 300°C. Ensure your manufacturer provides heat-treated, high-hardness materials that won’t deform or lose dimensional stability.

c) Precision and Repeatability

Semiconductor tools require micron-level accuracy. Confirm that your manufacturer uses CNC machining, EDM finishing, and optical measurement to guarantee repeatable precision across production runs.

d) Compatibility with Mold Design

The manufacturer should be able to custom-engineer ejector pins that align perfectly with your mold’s cavity and layout. Some advanced manufacturers even offer 3D modeling support or design validation to ensure fit and function.

4. Evaluate Quality Certifications and Traceability

A reliable ejector pins manufacturer should demonstrate strict quality assurance processes. Look for certifications such as:

- ISO 9001: Quality management system.

- ISO 14001: Environmental management.

- IATF 16949: Automotive-grade manufacturing standards (often a good sign of consistency).

In semiconductor manufacturing, traceability is also vital. A good manufacturer should provide full documentation — from material batch certificates to surface finish reports and inspection data — ensuring every part meets required standards.

5. Assess Customer Support and After-Sales Service

Reliable customer support can make a big difference in long-term partnership success.

Ask the following questions:

- Do they provide technical consultation during the design phase?

- Can they recommend materials or coatings based on your application?

- Do they offer regrinding, replacement, or refurbishment services?

- How fast is their response time for urgent orders or adjustments?

Manufacturers who understand semiconductor tooling requirements are often proactive in providing maintenance advice and scheduling predictive replacements — ensuring minimal downtime.

Quick Checklist for Selecting an Ejector Pins Manufacturer

| Criteria | What to Look For |

| Location | Proximity for fast lead times and on-site support |

| Product Variety | Full range of materials, coatings, and geometries |

| Semiconductor Compatibility | Cleanroom-ready, contamination-free materials |

| Precision Capability | CNC machining, optical inspection, micro-tolerances |

| Certifications | ISO 9001, ISO 14001, IATF 16949 |

| After-Sales Support | Consultation, regrinding, and rapid response services |

Conclusion: Partnering for Precision and Performance

In the semiconductor industry, even the smallest component can make a big difference. Choosing the right ejector pins manufacturer ensures your production processes remain efficient, precise, and contamination-free.

By considering location, product variety, and application fit, manufacturers and engineers can form partnerships that deliver long-term value — not just short-term savings.

When evaluating suppliers, prioritise those who understand the unique demands of semiconductor applications and have the technology, experience, and certifications to back it up.

Ready to find precision-built ejector pins for your semiconductor molds?

👉 Explore Leader Hi-Tech’s range of high-performance ejector pins, engineered for accuracy, cleanliness, and long-term reliability in advanced semiconductor applications.

As an ISO 9001:2015 certified manufacturer, Leader Hi-Tech upholds the highest standards of quality management, traceability, and consistency, ensuring every component meets the demanding requirements of semiconductor production.