When it comes to precision machining and manufacturing, one of the most critical components for cutting tools is carbide tips. Whether you’re a business owner looking to improve your machining operations or seeking a solution for more durable cutting edges, understanding the different types of carbide tips for interchangeable inserts and cutting edges is crucial.

These tools are integral to achieving high-performance results in a variety of industries, from metalworking to woodworking and automotive manufacturing.

In this article, we will explore the various types of carbide tips, their applications, and how to choose the right carbide tools for your business’s needs.

By the end, you’ll be equipped with the knowledge to make informed decisions regarding your cutting tools and ensure optimal efficiency and longevity.

What Are Carbide Tips?

Carbide tips are made from a blend of carbide (typically tungsten carbide) and a binder material, often cobalt. The result is a highly durable material that is both hard and wear-resistant. Carbide tips are used in cutting tools for applications that involve high heat, pressure, and friction.

Due to their hardness, they are capable of cutting through hard materials such as metals, ceramics, and plastics with exceptional precision and durability.

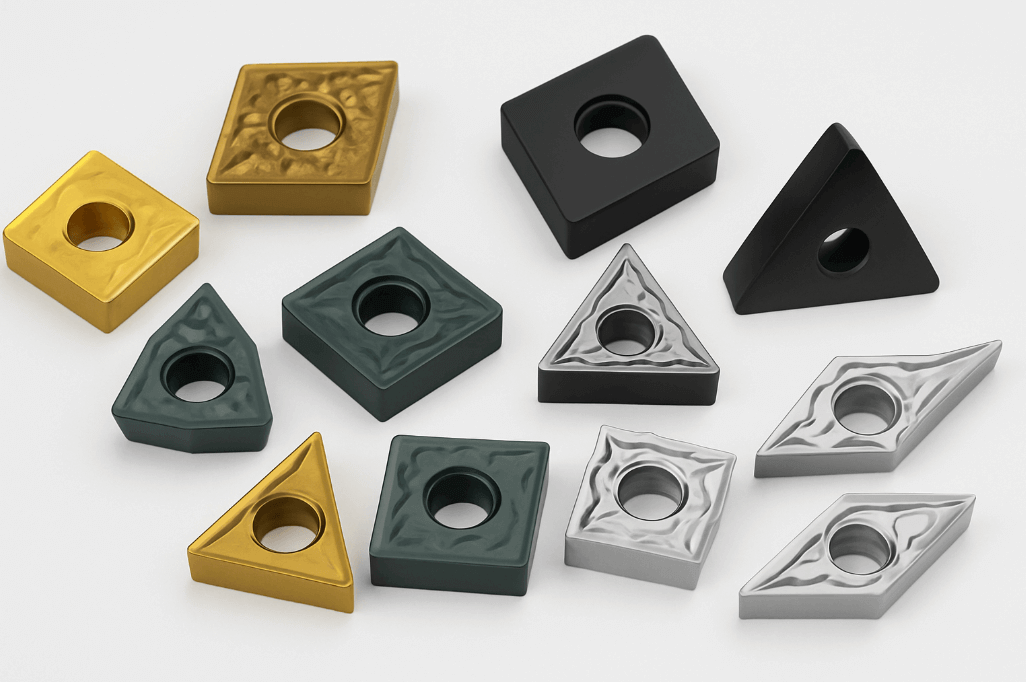

Carbide tips are typically attached to the cutting edges of tools such as drills, milling cutters, and inserts for turning operations. These tips come in a variety of shapes and sizes, depending on the specific requirements of the cutting task.

Types of Carbide Tips for Cutting Tools

When selecting the right carbide tools for your business, it’s essential to understand the different types available, particularly the carbide tips used in interchangeable inserts and cutting edges. Below, we will dive into the most common types of carbide tips and their applications.

1. Solid Carbide Tips

Solid carbide tips are one of the most popular options due to their exceptional hardness and wear resistance. These tips are made entirely of carbide material, providing outstanding durability and heat resistance.

Solid carbide tips are typically used in tools for high-speed cutting operations and in industries where precision is paramount, such as aerospace and automotive.

Applications:

- CNC cutting tools: For precise machining in materials like aluminum, steel, and composites.

- Milling cutters: To achieve clean and accurate cuts, especially in high-speed machining.

- Drills: For applications requiring deep hole drilling or working with tough materials.

Advantages: High wear resistance, exceptional durability, and the ability to maintain sharpness over extended periods.

2. Carbide-Tipped Inserts

Carbide-tipped inserts are interchangeable components that are used to replace the cutting edge of tools. These inserts are commonly used in turning, milling, and drilling applications. The carbide tip provides superior cutting performance, while the body of the insert is typically made from a tougher, more affordable material like steel.

This combination allows for the best of both worlds: the precision and wear resistance of carbide with the durability and cost-effectiveness of the base material.

Applications:

- Turning tools: Used in CNC lathes for turning operations on both ferrous and non-ferrous metals.

- Milling inserts: For milling operations where high precision and surface finish are required.

- Drill bits: In situations where standard drills would wear too quickly or fail.

Advantages: Cost-effective compared to solid carbide tools, high durability, and ease of replacement.

3. Cermet Carbide Tips

Cermet carbide tips combine carbide with ceramic materials, such as titanium carbide or aluminum oxide, to create a material that is even harder and more wear-resistant than solid carbide.

These tips are designed for high-precision cutting operations in industries where the surface finish is critical, such as automotive or die-casting industries.

Applications:

- Precision turning: Ideal for hard-to-machine materials and for applications requiring a high-quality surface finish.

- Cutting of tough materials: Perfect for use in high-speed machining where the cutting tool undergoes high heat and pressure.

Advantages: Extreme hardness, superior wear resistance, and the ability to achieve fine surface finishes even on difficult materials.

4. Polycrystalline Diamond (PCD) Carbide Tips

PCD carbide tips are made from synthetic diamond particles that are bonded to a carbide substrate. These tips provide the hardest cutting edge available and are perfect for machining non-ferrous metals, composites, and some high-performance alloys.

PCD tips are commonly used in the aerospace, automotive, and semiconductor industries due to their ability to cut at high speeds while maintaining precision.

Applications:

- Non-ferrous metals: Ideal for cutting aluminum, copper, and brass.

- Composite materials: Used for machining advanced composite materials, such as carbon fiber and fiberglass.

- High-performance alloys: For applications requiring high-speed cutting and extreme hardness.

Advantages: Extremely high wear resistance, superior edge retention, and ideal for cutting hard, abrasive materials.

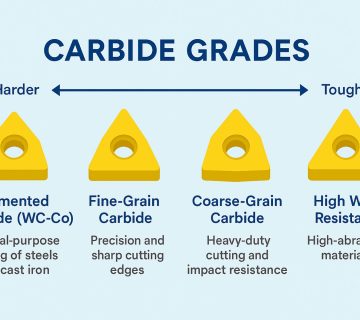

5. Cobalt Carbide Tips

Cobalt carbide tips are a mix of tungsten carbide and cobalt. While not as hard as solid carbide or PCD, cobalt carbide is more flexible and resistant to shock, making it suitable for applications that require both strength and resilience.

These tips are commonly used in cutting tools where toughness is more important than absolute hardness.

Applications:

- Heavy-duty machining: Ideal for turning, milling, and drilling tough materials like cast iron, high-carbon steels, and other alloys.

- Applications involving shock loading: Great for operations that involve intermittent or aggressive cuts.

Advantages: Tougher than solid carbide, more resistant to shock, and better for applications involving heavy cutting loads.

How to Choose the Right Carbide Tips for Your Business

Choosing the right cutting tools with the appropriate carbide tips is essential for optimizing your manufacturing processes. Here are some factors to consider when selecting carbide tips:

1. Material to Be Cut

Different materials require different types of carbide tips. For instance, PCD carbide tips are perfect for cutting non-ferrous metals and composites, while solid carbide tips or cermet carbide tips may be better suited for high-speed machining of tougher materials like steel or titanium.

2. Type of Machining Operation

Consider the type of machining operation you are performing. If you’re working with high-speed milling or precision turning, solid carbide or PCD carbide tips will be best. For general-purpose machining or turning, carbide-tipped inserts can offer a more cost-effective solution while still providing good performance.

3. Durability and Wear Resistance

If you need tools that can handle heavy-duty cutting, opt for materials with higher wear resistance, such as PCD carbide or cermet carbide. These materials can withstand high temperatures and abrasive materials, extending the lifespan of your tools and reducing downtime.

4. Cost Efficiency

While solid carbide tips offer exceptional performance, they may not be the most cost-effective solution for all applications. If your budget is tight or if you’re cutting materials that don’t demand the highest precision, consider using carbide-tipped inserts for a more affordable option.

Conclusion

The right carbide tips for your cutting tools can make a world of difference in your manufacturing processes. From solid carbide tips to PCD carbide inserts, each type of carbide material offers unique advantages depending on your machining needs.

By carefully considering the material you are cutting, the type of machining operation, and your durability requirements, you can select the best carbide tips that will ensure precision, cost-efficiency, and longevity in your operations.

As a business owner, it’s essential to choose your cutting tools wisely to maximize productivity and minimize downtime. Whether you’re looking for high-performance CNC cutting tools or carbide tools for general-purpose machining, understanding the different types of carbide tips will help you make more informed decisions and improve your bottom line.