Precision Tooling Manufacturer for Semiconductor Industry

LeaderRange Hitech Sdn Bhd

About our company

We’re more than just a semicon tools and accessories provider. ISO 9001:2015 UKAS certified with a functional QMS, our products are proven through 18 years of use.

Manufacturer, Distributor, Partner.

Semiconductor Tools & Accessories Supplier Since 2006

LeaderRange Hitech Sdn Bhd 724799–P initiated operation in 2006 as a manufacturer of world class Semiconductor Machine Tools and Accessories. In Malaysia, we strive to be leaders in cost cutting quality precision tools for the global market. Today, we’re servicing over 54 clients globally and 70% overseas.

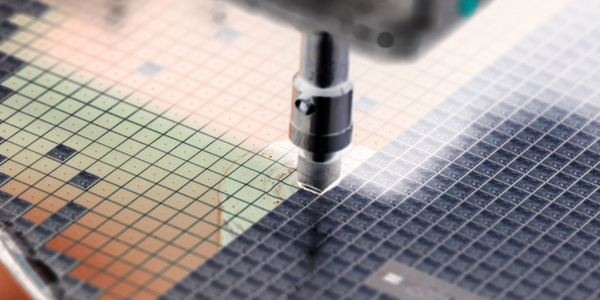

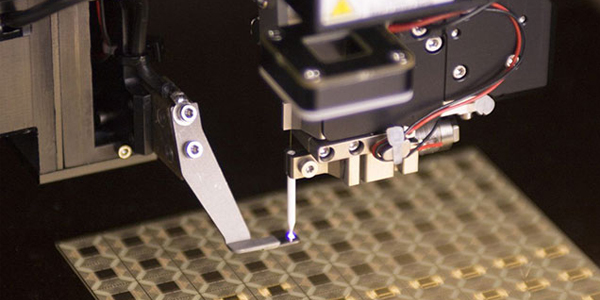

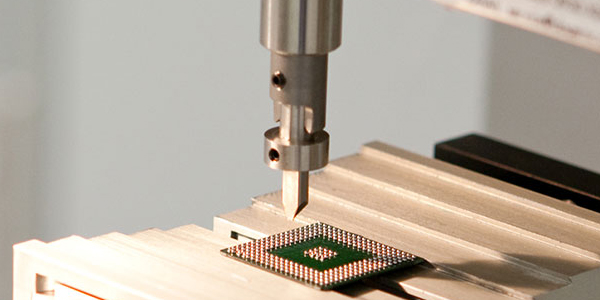

Discover our range of high-performance precision tooling solutions for various industrial needs. Our products include ejector pins and ejector needles for precise molding, durable rubber tips and carbide tips for enhanced performance, and reliable shear pins and shear tools for accurate bond strength testing. We also offer the versatile wire pull hook for efficient wire handling and epoxy stamping tools for superior precision. All products are engineered for exceptional quality and reliability.

The Things We Do Best

Manufacturer, Distributor, Partner

Priority Support

When production is on the line, you need a team

thats responsive and obligated to your needs

Product Assurance

Our products are assured and we’ll commit to a refund

or a replacement if the product is unsatisfactory

Cost Down

We’re the experts at bringing your cost down

with no compromise on quality

Connected

We’re up to date with the latest designs and materials.

There’s no job we cant handle

Global Markets

Connect with us

Get in touch and we’ll help turn things your way

What We Offer

Product Description for Precision Tools

Standard Tungsten Carbide (WC)

Ejector Needle (R0.015 – R0.350mm)

Ejector needle used in all Semicon Die Bond chip machines, offering high lifespan cycle. Suitable for all types of bonder makers like ASM, KNS, ESEC, Mi, Shinkawa and so on.

Round Micro Series (7 – 10mils)

Rubber collet used in all Semicon Die Wire Bond Tape & Reel chip machines for pick and place. Suitable for all types of bonder makers like ASM, KNS, ESEC, Mi, Shinkawa and so on.

DAGE 4000 Tester Series Standard Size

Wire Pull Hook used to accurately test the Die bond strength, for testers such as DAGE, XYZ, SIGMA, ROYCE, F&S Bonder Testers.

Customization Available

Our design team specializes in tools for complex chips, including COB, Non-Glassified, Bump Dies, Flip Chips, Encapsulated, and Ultra-Thin Dies (under 2 mil). We provide solutions for a wide range of die and chip challenges.

FAQs About Precision Tooling Solutions

Semiconductor machine tools and accessories are specialized equipment and components used in the manufacturing, testing, and handling of semiconductor devices.

These tools include precision instruments like ejector pins, shear tools, wire pull hooks, and carbide tips, all designed to perform critical tasks such as die bonding, wire bonding, and component testing. They ensure high accuracy, reliability, and efficiency in semiconductor production processes.

Accessories like these are essential for maintaining tight tolerances and quality control in the production of microchips, semiconductors, and other precision components used in electronics.

Precision tooling in the semiconductor industry refers to specialized tools and equipment used to manufacture high-precision components with extremely tight tolerances. Since semiconductor parts are microscopically small, even the slightest error can cause defects.

These tools ensure accuracy, consistency, and reliability in machining, assembly, and wafer handling. They are designed to withstand high-speed operations and strict manufacturing standards, helping produce efficient and defect-free semiconductor components. Read more info here.

Precision tooling in semiconductor machine tools and accessories refers to the high-accuracy components and tools used in the manufacturing and testing of semiconductor devices. These tools, such as ejector pins, shear tools, and wire pull hooks, are designed to meet exact specifications, ensuring optimal performance in critical processes like die bonding, wire testing, and component handling.

Precision tooling is crucial in the semiconductor industry because it guarantees the accuracy, reliability, and consistency of manufacturing processes, leading to high-quality products and minimizing defects in sensitive semiconductor components.

Yes, LeaderRange HiTech is an ejector pins manufacturer of semiconductor machine tools and accessories, including ejector pins. Their product line features the Hybrid Red Ejector Pin, which is part of their Die Bond Tools category. This indicates their capability in producing specialized ejector pins for semiconductor manufacturing processes.

In semiconductor manufacturing, shear pins are precision tools made from high-hardness materials like carbide, designed to test the bond strength of die attachments by applying controlled force until failure. This process ensures the reliability of the die bonds. Shear tools encompass a broader category of equipment used in shearing processes, including various components that facilitate precise cutting and shaping of materials. Both are essential for quality assurance in semiconductor production.

👉 Learn more about the differences between shear pins and shear tools in detail. Read the full blog here.