Category: Die Bond Tools

What are Tungsten Carbide Tips?

Carbide tips are small yet powerful components made primarily from tungsten carbide, a compound known for its extreme hardness and superior wear resistance.

These tips are engineered to deliver exceptional cutting performance and durability, making them indispensable across industries such as metalworking, woodworking, construction, mining, and semiconductor manufacturing.

Unlike complete tools like carbide pickup tools, carbide tips serve as interchangeable inserts or cutting edges that are integrated into a wide range of tools—such as drill bits, saw blades, milling cutters, and lathe tools.

Their main function is to provide a hard, heat-resistant, and wear-resistant edge for cutting, drilling, and machining tasks, especially in high-speed, high-friction environments.

Our Variety of Carbide Tips

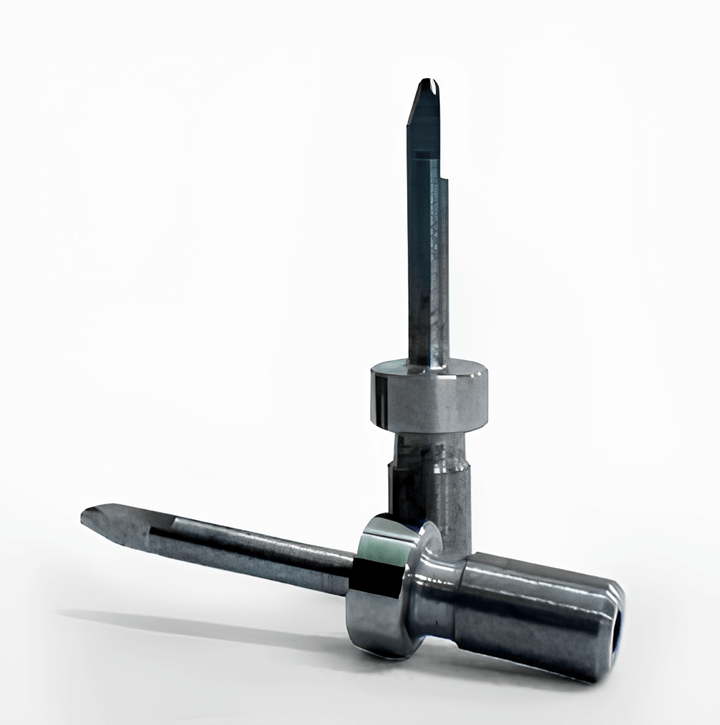

Standard Tungsten Carbide (WC) Ejector Needle

Type: Standard Tip

Key Characteristics:

Radius (R): R0.015mm – R0.350mm

Straightforward design for general-purpose ejection

Applications: Ideal for standard ejection processes requiring durability and precision.

Flat Tip Tungsten Carbide (WC) Ejector Needle

Type: Flat Tip

Key Characteristics:

Diameter (Dia): 0.020mm – 0.700mm

Flat end design for specific ejection needs, ensuring even pressure distribution.

Applications: Suitable for applications needing precise surface contact, such as delicate or flat-surface components.

Step Ejector Pin

(WC)

Type: Step Tip

Key Characteristics:

Radius (R): R0.015mm – R0.350mm

Step design enhances functionality for multi-level ejection tasks.

Applications: Used in situations requiring varying levels of ejection force or distance within a single operation.

Our Carbide Tips

USED IN ALL SEMICON SMT

CARBIDE AND STEEL COLLET

USED IN DIE BOND MACHINES

Key Features of Carbide Tips

Designed for exceptional performance, carbide tips combine advanced material properties with precision engineering to meet the demands of industrial and professional applications.

1. Exceptional Hardness and Durability

Crafted from tungsten carbide, carbide tips boast an impressive hardness rating of 82–85 HRC, positioning them just below diamond on the hardness scale. This extreme hardness gives them:

-

Outstanding wear resistance, even under intense, repetitive use

-

Extended tool lifespan, reducing replacement frequency and operational downtime

-

The ability to maintain sharp edges under high mechanical stress

2. Outstanding Heat Resistance

Carbide tips are built to perform in high-heat environments, with a maximum working temperature of up to 2000°C. This makes them ideal for:

-

High-speed machining

-

Dry cutting operations

-

Applications where thermal deformation is a concern

-

Their thermal stability ensures reliability and accuracy even under extreme operational conditions.

3. Mirror Surface Finish for Superior Precision

These carbide tips are capable of achieving a flawless, glossy, and ultra-flat surface finish. The benefits of this mirror-like finish include:

-

Increased contact area for improved efficiency

-

Greater cutting precision and cleaner finishes

-

Reduced friction, resulting in smoother performance and longer life span

-

This level of finish is especially valuable in sorting tools and precision machining, where surface quality directly impacts output quality.

4. Versatility Across High-Performance Applications

Carbide tips are a versatile component used in:

-

Cutting tools (e.g. saw blades, lathe tools, end mills)

-

Pick-up tools for sorting automation systems

-

High-precision industrial machines used in electronics, aerospace, woodworking, and metal fabrication

-

Wherever precision, durability, and heat resistance are mission-critical, carbide tips deliver unmatched results.

The Smart Choice for Demanding Industrial Tasks

With their superior hardness, exceptional thermal resistance, and refined surface finish, carbide tips represent a cost-effective, high-performance solution for professionals seeking durability, accuracy, and long-term reliability.

Whether you’re producing thousands of cuts a day or operating in high-temperature machining conditions, carbide tips are built to perform—time after time.

Frequently Asked Questions About Carbide Tips

What are carbide tips in a semiconductor die bond machine?

Carbide tips in a semiconductor die bond machine are precision-engineered components made from tungsten carbide (WC), a highly durable and wear-resistant material. These tips are typically used in ejector pins or bonding tools to handle and position semiconductor dies during the die bonding process. Their high hardness and precision make them essential for achieving accurate die placement.

Why are carbide tips important in semiconductor die bonding?

Carbide tips are crucial in semiconductor die bonding due to their durability, precision, and resistance to wear and deformation. They ensure consistent performance under high-pressure or high-temperature conditions, protect delicate semiconductor dies during handling, and maintain their shape even after repeated use. This reliability enhances the efficiency and quality of the die bonding process.

Why is cobalt used as a binder in carbide tips?

Cobalt is commonly used as a binder in carbide tips because it enhances toughness and helps hold the tungsten carbide particles together. This combination provides a balance between hardness and shock resistance, making carbide tips more durable and reliable during high-speed or heavy-duty cutting applications.

Why are carbide tips preferred in cutting tools?

Carbide tips are highly valued for their exceptional hardness and resistance to wear and heat. They enable extended tool life, precise cutting, and reliable performance, especially in demanding machining applications.

About LeaderRange Hitech Sdn Bhd

At LeaderRange HiTech, we specialize in high-performance ejector pins and carbide tips, engineered for precision handling in semiconductor manufacturing. Designed for durability and accuracy, our carbide tips enhance die bonding, pick-and-place processes, and precision tooling, ensuring superior performance in demanding applications.

Whether for standard or specialized semiconductor processes, our carbide tips provide exceptional wear resistance, minimal material contamination, and high precision to optimize production efficiency. Committed to quality and innovation, we offer customizable carbide solutions, serving both local and international markets with excellence.