Category: Die Bond Tools

Your Trusted Ejector Needle & Ejector Pins Manufacturer

Leader Hi-Tech, a reliable ejector pins and needle manufacturer, provides precision tooling solutions with ejector pins made from various materials to accommodate the sensitivity and specific requirements of different applications. We offer customized tip sizes and options to ensure the perfect fit for your needs. Available in various sizes and configurations, our ejector needles are engineered to meet diverse production needs with precision tooling expertise.

What Is an Ejector Pin or Ejector Needle?

Ejector pins, also known as ejector needles, are essential components in the injection moulding and die-casting process. Their primary function is to push out moulded parts from the mould cavity once the material has cooled and solidified.

By applying a controlled mechanical force, they ensure smooth part removal without damaging the product, which is critical for maintaining dimensional accuracy and surface integrity.

These pins are typically made from hardened steel or carbide, chosen for their durability, wear resistance, and precision. Different materials and designs are selected based on specific application needs—especially in high-precision industries like semiconductor manufacturing, where tight tolerances and part integrity are paramount.

Types of Ejector Pin Materials and Their Properties

- Tungsten Carbide: The hardest material offered, known for its exceptional wear resistance and strength. Ideal for high-stress applications where durability is key.

- High-Speed Steel: Provides a good balance of hardness and toughness, making it suitable for general-purpose applications.

- Red Ultem Plastic: A softer material that offers high precision and is gentle on delicate parts, preventing damage during the ejection process.

- Translucent Ultem Plastic: The softest material in the range, providing high precision and reducing the risk of marking or damaging sensitive components.

Explore the different types of ejector pins to find the perfect fit for your moulding needs — precision starts with the right choice.

Ejector Pin Selection Criteria

The choice of ejector pin material depends on several factors:

Die Dimensions: Larger or more complex dies may require harder materials for effective ejection without deformation.

Material: The type of material being molded will influence the choice of ejector pin. Harder materials may be necessary for tougher molded parts.

Needle Holder Settings: Default settings and specific requirements of the needle holder will also determine the most suitable material for the ejector pins.

Our Ejector Pins

TRANSLUCENT YELLOW PLASTIC PIN

HYBRID RED EJECTOR PIN

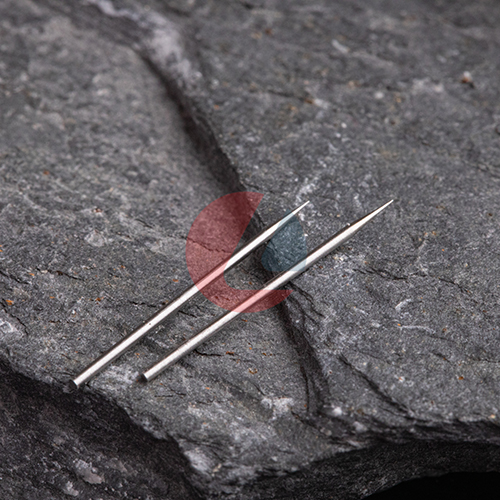

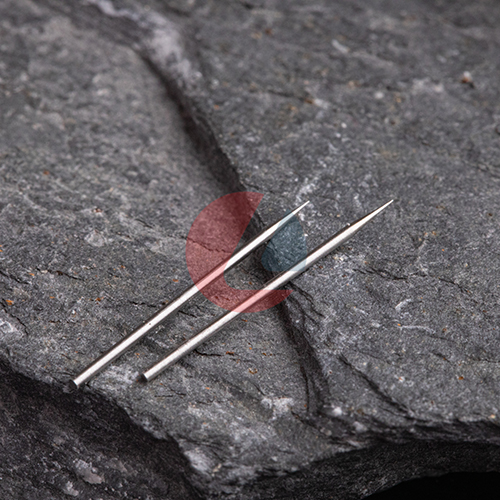

HSS & TUNGSTEN EJECTOR PIN

Key Differences Ejector Pins vs. Ejector Needles

In precision tooling for semiconductor and mold manufacturing, ejector pins and ejector needles serve a similar function – removing molded or machined parts from the mold or tool. However, they differ in design, application, and precision level.

Ejector pins are ideal for general ejection in molding, while ejector needles are used for precision applications requiring gentle and accurate part removal.

✅ Ejector Pins:

- Thicker and more rigid, designed for standard ejection of molded components.

- Used in plastic injection molding and die casting.

- Provides strong, stable force to push out parts.

✅ Ejector Needles:

- Much thinner and finer, designed for delicate and small components.

- Used in semiconductor and micro-molding applications.

- Prevents damage to fragile or high-precision parts during ejection.

About LeaderRange Hitech Sdn Bhd

We are a leading ejector pins manufacturer in the semiconductor machine tools and accessories industry. With a commitment to quality and precision, we offer a wide range of products, including ejector pins and ejector needles, designed to meet the diverse needs of the semiconductor industry.

Focused on innovation and customer satisfaction, LeaderRange HiTech delivers excellence in semiconductor manufacturing, serving both local and international markets.

FAQs About Ejector Pins and Ejector Needles

How do ejector pins work in injection molding?

Ejector pins play a crucial role in injection molding by pushing the molded part out of the mold cavity after cooling. They ensure smooth ejection, prevent defects, and improve overall production efficiency. Proper alignment and material selection are key to avoiding damage to both the mold and the finished product.

What are common challenges with ejector pins, and how can they be prevented?

Common issues include wear and tear, misalignment, and breakage due to high pressure or improper installation. Using high-quality materials, ensuring precise alignment, and selecting the right coating can help extend the lifespan of ejector pins while maintaining production efficiency.

How can I extend the lifespan of my ejector pins?

To maximize durability, regularly lubricate the pins to reduce friction, ensure proper alignment during installation, and store them in a clean, dry environment to prevent corrosion. Periodic inspections and timely replacements also help maintain optimal performance.

What factors should I consider when selecting ejector pins for my application?

When choosing ejector pins, consider factors like material composition, coating options for wear resistance, pin diameter, length, and the specific requirements of your mold design. For high-precision applications, selecting customized ejector pins can enhance efficiency and product quality.